Samsung pushes power savings in its chargers

Standby power consumption in smart device chargers is considered to be a major contributor to the pressing problem of power waste.

Samsung has been reducing the standby power consumption of its chargers using software, starting with the flagship Galaxy chargers which were reduced to 20mW in 2012. Since then, Samsung has been moving the technology into the chargers for devices throughout its product range.

“In order to supply a smartphone with power as soon as it’s connected, a charger must always be ‘running,’” said Wonseok Kang, an engineer in Samsung’s Mobile Communications Business’s Power Solution Group. “In the past, we simply kept the charger running without regulation. Now, we’ve packed software into the charger that puts it to sleep when a device is unplugged – reducing power consumption to a more environmentally conscious voltage level – and wakes the charger up when a device is connected. It’s an energy-efficient cycle of sorts.”

Like standby power consumption, charging efficiency is a key determinant of just how environmentally conscious a charging technology will be. Galaxy smartphones’ chargers have an energy efficiency rating of over 80 percent, which meets the European Union’s standard for Level VI ErP (Energy-Related Products) certification.

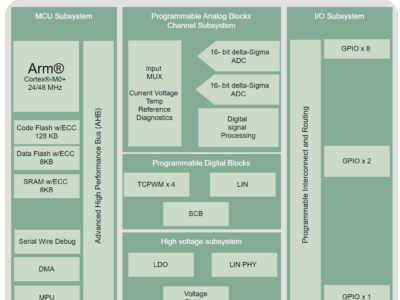

This efficiency level highlights Samsung’s use of silicon rather than wide bandgap technology such as gallium nitride which can achieve efficiency levels over 95 percent with higher power levels up to 60 or 100W – GaN CHIPS BOOST POWER SUPPLY DESIGN TO 75W

However there are new techniques such as active switching to boost silicon performance: ACTIVE SWITCHING AC-DC CONTROLLER USES SILICON OVER GaN, especially with the vlumes that Samsung ships (see below).

As a result, Samsung’s developers went to great lengths to enhance the energy efficiency of its chargers, analyzing even the tiniest of components in an effort to maximize functionality. “We focused mainly on improving the circuits of the semiconductors that are used to convert energy,” said Kang. “In the end, we were able to reduce the cumulative electric charge by minimizing energy loss.”

“As mobile devices evolve and battery capacities increase, charger specifications have to increase as well,” said Kang. “From 15 watts to 25, to 45W and beyond, higher specifications require greater functionality. This inevitably leads to a decrease in average energy efficiency. However, our commitment to designing the most efficient chargers possible enabled us to deliver a high level of efficiency with likewise high specs.”

Even the modest efficiency gain provides benefits when Samsung ships millions of devices. The company shipped 540m 15W and 25W Galaxy smartphone chargers between 2014 and 2019, which saved approximately 350m kWh compared to the 100mW Level VI standard of Europe’s ErP specification and the United States’ Department of Energy requirements.

The next challenge is the new USB-C Power Delivery (PD) designs that are driving 100W chargers.

The Samsung chargers also use recycled plastic to reduce waste. Galaxy smartphone chargers use around 20 percent of post-consumer materials (PCM) made from recycling the resources of previously owned products. As of 2019, approximately 5,000 tons of PCM have been used to manufacture Galaxy smartphone chargers.

Samsung’s developers worked hard to ensure that adding PCM to charger designs wouldn’t compromise the overall quality of the final products. “Adding PCM can affect a product’s durability or performance,” said Pranveer Singh Rathore, an engineering colleague of Kang’s from Samsung’s Advanced CMF Lab. “However, after numerous attempts, we managed to make our designs both aesthetically pleasing and satisfyingly durable, while preserving the intrinsic properties of the substance.”

Safety is a key factor in using recycle materials, as the chargers are sensitive to heat and must therefore be adequately flame retardant. “Prioritizing recycled materials and satisfying strict flame-retardancy standards at the same time was quite a challenge,” said Rathore. “However, by collaborating with various divisions and departments, we were able to come up with a method to increase the product’s quality and prevent the physical properties of the material itself from deteriorating.”

“It is never easy to go beyond the existing legal standards and design products that consider the environment – especially when other companies aren’t doing the same,” he said. “Nevertheless, I am confident that Samsung’s efforts will positively affect green initiatives going forward.”

“Raising awareness of things like smartphone chargers’ power consumption may eventually lead consumers to consider energy efficiency as an important factor when choosing a new device,” said Kang.

Related articles on chargers

- 750V GaN SWITCHES TARGET 55W POWER DELIVERY DESIGNS

- EPC TAKES ON SILICON OVER GaN RELIABILITY

- 120W EXTERNAL POWER ADAPTER FOR HOME HEALTHCARE

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News