Red phosphorus protects lithium metal batteries

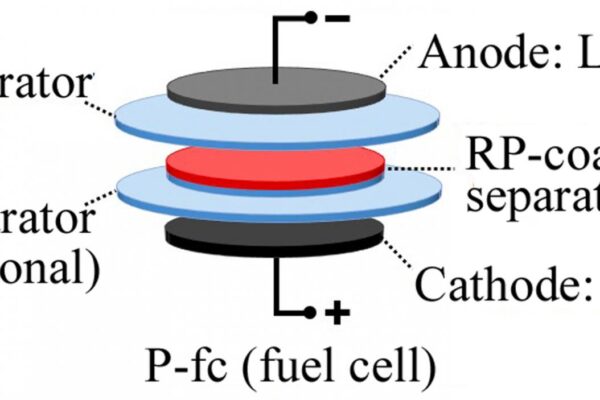

The lab of chemist James Tour made test cells with a coat of red phosphorus on the separator that keeps the anode and cathode electrodes apart in lithium metal batteries. These can charge much faster and hold about 10 times more energy by volume than common lithium-ion batteries. The phosphorus acts as a trigger for management systems used to charge and monitor batteries by detecting the formation of the dendrites tha can caouse short circuits.

With a red phosphorus-coated separator in the way, when a dendrite grows and touches the separator, the battery’s charging voltage changes. This tells the battery management system to stop charging. Unlike other proposed dendrite detectors, this approach doesn’t require a third electrode, and has no significant effect on normal performance in experiments on test batteries by the Tour lab.

“Manufacturing batteries with a third electrode is very hard,” said Tour. “We propose a static layer that gives a spike in the voltage while the battery is charging. That spike is a signal to shut it down.”

The researchers built a transparent test cell with an electrolyte known to accelerate aging of the cathode and encourage dendrite growth to monitor the voltage while the dendrites grow. With an ordinary separator, the team saw the dendrites contact and penetrate the separator with no change in voltage, a situation that would lead a normal battery to fail. With the red phosphorus layer, there was a sharp drop in voltage when the dendrites contacted the separator.

“As soon as a growing dendrite touches the red phosphorus, it gives a signal in the charging voltage,” said Tour. “When the battery management system senses that, it can say, ‘Stop charging, don’t use.'”

Last year, the lab introduced carbon nanotube films that appear to completely halt dendrite growth from lithium metal anodes. “By combining the two recent advances, the growth of lithium dendrites can be mitigated, and there is an internal insurance policy that the battery will shut down in the unlikely event that even a single dendrite will start to grow toward the cathode,” said Tour.

“Literally, when you make a new battery, you’re making over a billion of them,” he said. “Might a couple of those fail? It only takes a few fires for people to get really antsy. Our work provides a further guarantee for battery safety. We’re proposing another layer of protection that should be simple to implement.”

Related stories:

- PROJECT BOOSTS SILICON ANODE PERFORMANCE

- SILA NANO RAISES $75M FOR SILICON ANODE BATTERY MATERIALS

- COMPOSITE CARBON ANODE TRIPLES BATTERY CAPACITY

- SILICON ANODE BOOST FOR LITHIUM SULFUR BATTERIES

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News