Hydrogen aims for cost parity with oil

Norwegian hydrogen technology developer Nel has detailed plans to produce hydrogen from renewable sources at $1.50/kg (€1.24/kg) to compete with fossil fuels such as petrol and diesel.

Scaling up of production to multi-GW scale, growing the organization to add capacities and capabilities, and investing in technology for the near- and long-term are crucial components in the strategy, says CEO Jon André Løkke.

This is backed up by a major project to convert a coal power station in Hamburg, Germany, into a massive 100MW hydrogen electrolyser.

“Green renewable hydrogen is set to outcompete fossil alternatives, and Nel is placed in the centre of this transition,” said Løkke at Nel. “We’re launching our target which should enable our customers in certain markets to produce green renewable hydrogen from a large-scale Nel facility at $1.5/kg from low cost renewable power, already within 2025. Achieving this would allow green hydrogen to start to reach fossil parity, representing one of the most significant achievement for zero-emission solutions and a carbon neutral planet.”

Hydrogen fuel cell technology will be a key capacity for electric vehicles in the future says Malcolm Penn of analyst Future Horizons as well as electric aircraft.

“The next step after battery electric vehicles is hydrogen and its good news for semicodnuctors as there more electronics required than in an EV,” said Penn. “It is gaining traction but the big issue is generating the hydrogen. There’s a lot of work going on the EU on that.”

Next: Green hydrogen production

To reach the $1.50/kg target, Nel is expanding its electrolysis production with a fully automated manufacturing facility at Herøya, Norway. Test production of the first 500 MW production line will start in the next few months with start of commercial ramp-up in the third quarter 2021. This will be able to produce systems that generate 2GW of hydrogen a year.

“Herøya represents the first industrial-scale production of the most efficient electrolysers on the market, at a game-changing low cost,” said Løkke. “A 2 GW production capacity of electrolysers would represent a potential of four-to-five million tons of CO2 reductions for our customers, or ten percent of the annual CO2 emissions in Norway.”

The current hydrogen market of 70 million tons is predicted to grow eight times by 2050.

“The market is already large, but with only a fraction served by electrolysis, there are significant opportunities to turn the existing market green. In addition, we see a regulatory landslide across the globe, with the EU and the US pledging hundreds of billions of dollars into their zero-emission programs where hydrogen serves a vital part as the energy carrier of choice,” said Løkke.

“The growth will not only come from industrial applications, but also from transforming the current diesel-based heavy-duty transportation to run on zero-emission and cost-efficient green hydrogen. These developments require low-cost electrolysis and ultra-fast fueling, both areas where Nel is the global leader,” he said.

“Nel uniquely covers both PEM and alkaline technologies, each with their respective advantages, and we will continue give them our full support and equal priority. The technology roadmap highlights our priority on large-scale products, continuous improvements, and lowest total cost of ownership for our customers. The hydrogen industry will become increasingly competitive and Nel therefore needs to continue to invest in organization, technology, and equipment to remain in the forefront of the industry,“ he added.

Nel has delivered more than 110 hydrogen fueling stations (HRS), H2Stations, in 13 different countries. The global HRS market is expected to grow by 30 percent a year towards 2030, with 11,000 installed fueling stations, in addition to solutions for fueling of private trailer parks, trains, ferries, etc.

“The only way to transform heavy-duty transportation is to beat diesel at the pump. In addition to green hydrogen reaching fossil parity at production, we have to enable fast fueling of hydrogen in a reliable and cost-efficient manner to be able to beat fossil alternatives. Nel has a technology roadmap enabling fueling in 10-15 minutes of a heavy duty truck to achieve a range of 1,000 km, and we are in a good position to continue to lead the hydrogen fueling industry,“ said Løkke.

However one of the major challenges is the distribution of hydrogen.

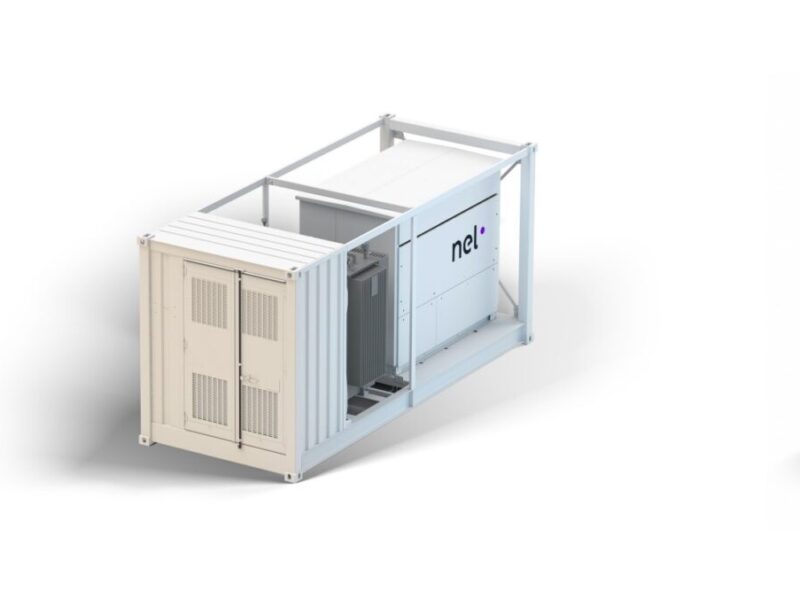

To address this, subsidiary NEL Hydrogen Electrolyser has launched two containerized Proton PEM electrolysers for automated local production from renewable energy.

“We are proud to officially launch the MC250 and MC500, representing automated MW-class on-site hydrogen generators utilizing a modular containerized design for ease of installation and integration. We are already experiencing significant interest for these solutions in the market,” says Filip Smeets, SVP Electrolyser Division of Nel.

The containerized MC250 and MC500 will be delivered as standard 1.25 and 2.5 MW (246 and 492 Nm3/h) versions and use Nel’s newly developed 1.25 MW PEM cell-stack, allowing for higher capacities per unit and lower cost. The design allows multiple units to be integrated easily in the field, which was a key consideration during the development.

“We are paying close attention to the market and our customers’ needs. With the containerized M Series Proton PEM electrolysers, we are offering the same robustness and reliability of our conventional M Series units, enabling faster and more flexible installation,” said Smeets.

The project in Hamburg brings together Vattenfall, Shell, Mitsubishi Heavy Industries and Hamburg’s municipal heat supplier Hamburg Wärme, but won;t be up and running until 2025.

The partners intend to apply for funding under the EU’s “Important Projects of Common European Interest” (IPCEI) programme.

“We are looking forward to having the opportunity to apply our engineering and technology expertise to realize this project together with our partners. The establishment of a green hydrogen hub that is fully integrated into Hamburg’s industrial infrastructure would show Europe and the world that the hydrogen economy is real and can make a significant contribution to the decarbonization of the energy system and heavy industry,” said Kentaro Hosomi, President and CEO Energy Systems, Mitsubishi Heavy Industries.

The electrolyser technology would come froo Vattenfall in Sweden. “In this project we can contribute with our expertise and experience and the unique Moorburg site that has the infrastructure that is necessary for large scale production of hydrogen. We are therefore pleased that we can support the city and the industrial location of Hamburg in implementing their ambitious climate goals,” said Andreas Regnell, Senior Vice President and Head of Strategic Development at Vattenfall.

nelhydrogen.com/product/m-series-c

Related hydrogen articles

- GERMANY LEADS EUROPE IN PATENTS AND FILLING STATIONS

- ABB TEAMS WITH AFC ENERGY ON FUEL CELL CHARGER

- BOSCH MOVES INTO THE POWER STATION BUSINESS USING UK TECHNOLOGY

Other articles on eeNews Power

- The power startup aiming to get Elon Musk’s attention

- MPS taps EPC for 48V GaN DC-DC converter

- Smallest energy harvesting chip for wearables and IoT

- Material boost for solid state battery technology

- Funding boost for UK second life battery startup

- $10m for grid optical sensor platform

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News