Giant CdTe crystals grown quickly for solar panels

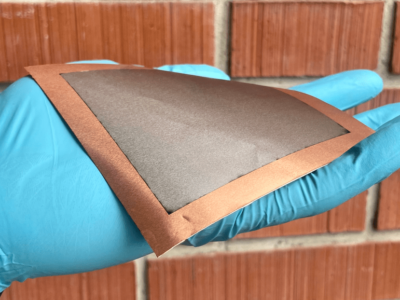

Researchers at Washington State University have developed a more efficient, safer, and cost-effective way to produce cadmium telluride (CdTe) material for solar cells.

The researchers showed they could rapidly grow a large amount of high-purity CdTe material, producing a1.2kg crystal in one day. Crystals up to 20kg can be grown say the team.

The technique uses a high-pressure furnace to produce large amounts of the needed crystal feedstock material and is 45 percent more cost effective than the industry standard and is scalable, which could make CdTe solar technology less expensive than natural gas. The crystal material produced also has better electrical properties than what is currently available.

CdTe photovoltaics are a newer technology than popular silicon solar cells and are competitive in terms of efficiency. They also perform better in hot and humid weather. While CdTe solar cells could provide significant advantages in cost and efficiency over silicon, they currently make up less than 10 percent of the solar market, mostly for large utilities as a result of the cost.

“Right now there is a huge kink in raw material production,” said Santosh Swain, research assistant professor with the Institute of Materials Research and a co-author on the paper. “The solar industry has steadily increased device efficiency and fabricating devices, but further efficiency gains and cost reduction require improvement in CdTe material properties.”

The current manufacturing process involves cooking the CdTe material in a sealed glass tube to contain the reaction. It takes a long time, the tubes are not reusable, and the silica glass is limited in how much heat, mass, and pressure it can take. Because of concerns about the material exploding, the industry is limited in the size of crystals they can grow. To make solar cells, the crystals are then evaporated onto glass substrate to make the thin films.

The new technique uses a strong graphite crucible, and the material is cooked in a high-pressure Bridgman furnace. The high-pressure environment completely eliminates the possibility of explosions and also allows the researchers to easily add a high concentration of additional materials, called dopants, during the manufacturing process that improve the material’s performance. Arsenic is added as a dopant. Adding the highly volatile dopants during the feedstock manufacturing process also eliminates the need to dope after film deposition which can cause non uniformity issues, said Tawfeeq Al-Hamdi, a PhD student and lead author on the paper.

“Doping is a key strategy,” said co-author Seth McPherson. “At 80 atmospheres of pressure, you can really shove the dopants into the material, and you don’t have to worry about them evaporating out of the crystal or otherwise escaping the system.”

The team worked with the National Renewable Energy Laboratory (NREL) and Nious Technologies in Pennsylvania.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News