Ultrasonic 3D printer builds circuit boards

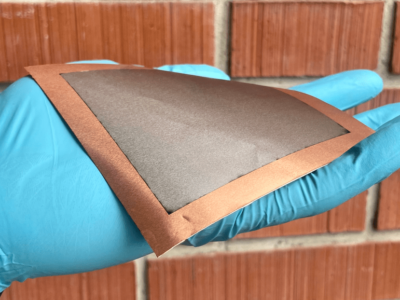

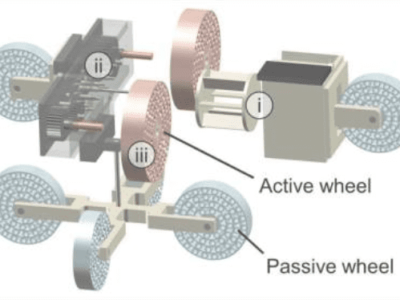

The team at the Ultrasound Research Group at Neurotechnology in Vilnius use the array of ultrasonic pulses (above) with feedback from a high resolution camera to move small objects around in the printer. This is particularly suitable for tiny components such as chip resistors. By increasing the frequency of the pulses, the placement resolution can be reduced to a few microns, says Dr Osvaldas Putkis, research engineer and project lead. Solder balls can be moved around with the array, and the parts are soldered to the board with a laser for a completely non-contact process.

Neurotechnology develops algorithms for biometric security and artificial intelligence systems and has patented the technology, which works with a wide range of solid and liquid materials and components, especially those that are vulnerable to electrostatic shocks.

“Ultrasonic manipulation can handle a very large range of different materials, including metals, plastics and even liquids,” said Pukis. “Not only can it manipulate material particles, it can also handle components of various shapes. Other non-contact methods, like the ones based on magnetic or electrostatic forces, can’t offer such versatility.”

The size of component depends on the size and strength of the array, but the prototype is limited to small devices measuring a few millimetres.

The company is looking at collaboration to further develop the technology.

Related stories:

- COMPACT, AFFORDABLE 3D PRINTER TARGETS ENTRY-LEVEL

- ZUKEN, NANO DIMENSION PARTNER FOR 3D CIRCUIT PRINTING

- NANO DIMENSION SHIPS FIRST 3D PRINTER FOR PCBS

- STARTUP USES IBM WATSON TO BUILD WORLD’S LARGEST SEARCH ENGINE FOR 3D PRINTABLE MODELS

- MIT’S LOW-COST MULTIFAB 3D PRINTER HANDLES 10 MATERIALS AT ONCE

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News